In the high-speed world of Formula 1, where every millisecond counts, the **Formula 1 skid block** plays a crucial role in ensuring driver safety and maintaining competitive performance. This seemingly simple wooden plank is a vital component designed to protect the car’s floor while also regulating downforce, a key factor in F1 car aerodynamics. With strict adherence to **F1 safety regulations**, the skid block functions as a safeguard against excessive wear and tear that can arise from the extreme conditions of racing. Interestingly, despite its protective purpose, the skid block’s design features require a specific thickness, compelling teams to rethink their strategies for ground clearance. This regulation, introduced after tragic accidents in the past, highlights how the skid block has become an essential element in the ongoing evolution of safety measures in Formula 1.

In the realm of Formula 1 racing, the term “skid block” refers to a critical safety feature that ensures the integrity of the car’s undercarriage. Often described as a protective plank, this component is central to the overall design of F1 vehicles, influencing not just the car’s aerodynamics but also its interaction with the track surface. Adhering to stringent **F1 safety standards**, the skid block serves the dual purpose of minimizing wear on the chassis while simultaneously limiting excessive downforce. Its function is particularly important during high-speed maneuvers, where maintaining control is essential. As teams prepare for races, understanding the significance of the skid block becomes crucial for optimizing performance and adhering to safety regulations.

Understanding the Function of the Formula 1 Skid Block

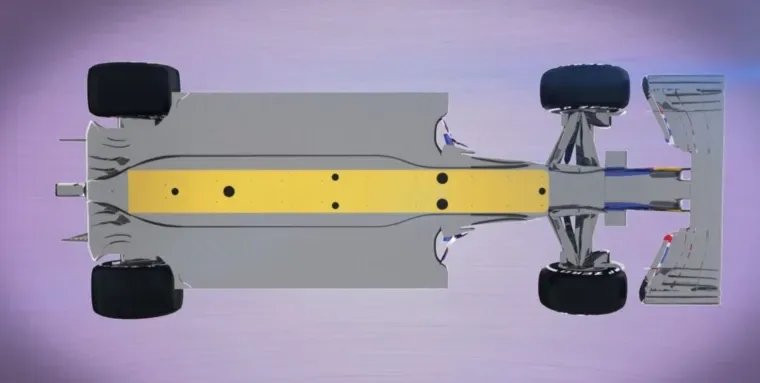

The skid block in Formula 1 serves a crucial role beyond simply being a wooden plank affixed to the car’s underside. It is designed to protect the car’s floor from damage and to limit the downforce generated during high-speed maneuvers. This function is vital because excessive downforce can lead to loss of control, particularly on uneven track surfaces. By maintaining a specific thickness, the skid block helps ensure that cars do not ride too low to the ground, which could result in dangerous ground effects and instability, especially when navigating challenging circuits.

Moreover, the skid block is not just a passive element; it actively contributes to the car’s aerodynamics. When a car’s suspension compresses, the skid block makes contact with the track surface, which can alter airflow around the car. This interaction can affect drag and lift, integral components of Formula 1 car design. Thus, understanding the skid block’s function is essential for grasping the intricate balance of safety and performance that defines modern F1 engineering.

The Impact of F1 Safety Regulations on Car Design

Following tragic events like the 1994 San Marino Grand Prix, Formula 1 has made significant strides in enhancing driver safety through stringent regulations. These regulations encompass various aspects, including the design features of the cars themselves, such as the skid block. By mandating specific safety components, F1 aims to minimize the risk of accidents and enhance the survivability of drivers in case of crashes. The introduction of the skid block regulation, for instance, was a direct response to the need for better protection and control under extreme racing conditions.

Regulatory changes often involve a collaborative effort between teams, engineers, and governing bodies like the FIA. The continuous evolution of F1 safety regulations not only affects components like the skid block but also drives innovation in overall car design. Teams are now required to consider how every part of the car, from aerodynamics to crash structures, contributes to driver safety. This holistic approach has led to the development of cars that are not only faster but also significantly safer, embodying the spirit of Formula 1 racing.

The Significance of Skid Block Thickness and Inspection

One of the critical aspects of the skid block’s role in Formula 1 is its mandated thickness, which must remain uniform at one centimeter throughout the race. This specification is crucial for ensuring that cars maintain an appropriate ride height, which is essential for optimal handling and safety. If a skid block wears down excessively—more than the allowable one millimeter—it becomes a serious issue, potentially leading to disqualification. This strict regulation underscores the importance of meticulous car management during race weekends.

Inspection of the skid block occurs at four designated points on the underside of the car, where teams can apply metal plates to reduce wear. This practice highlights the balance teams must strike between performance and compliance with safety regulations. Successful management of skid block integrity not only affects race outcomes but also reflects the technical prowess of the engineering teams. As recent disqualifications have shown, teams must remain vigilant; failure to adhere to these regulations can lead to severe penalties and loss of championship points.

Adapting to the Evolving F1 Regulatory Landscape

The landscape of Formula 1 regulations is constantly evolving, influenced by advancements in technology, safety concerns, and environmental considerations. As the sport moves towards greater sustainability, the upcoming changes to engine regulations in 2026 will likely impact various design features, including those related to the skid block. Teams will need to adapt their designs to meet new standards while still prioritizing performance and safety. This evolution is indicative of how F1 continually seeks to balance innovation with responsible racing.

Additionally, the introduction of hybrid power units and sustainable fuels will necessitate a reevaluation of all components, including the skid block’s design and material composition. As teams strategize to optimize aerodynamics and reduce weight, understanding the interplay between these factors and safety regulations will be crucial. This dynamic environment pushes teams to innovate continuously while ensuring that driver safety remains paramount, reflecting the ongoing commitment of Formula 1 to both performance and protection.

Case Studies: Recent Skid Block Disqualifications

Recent incidents involving skid block disqualifications have underscored the importance of compliance with F1 safety regulations. At the 2023 United States Grand Prix, both Lewis Hamilton and Charles Leclerc faced penalties due to excessive wear on their skid blocks. Such disqualifications serve as a reminder of the rigorous standards that teams must adhere to and the consequences of oversight. The tight schedules during race weekends often lead to increased pressure on teams, making it essential for them to prioritize meticulous inspections and maintenance of critical components.

These cases highlight the intense competition within Formula 1, where every millimeter counts, not just in terms of performance but also compliance. The reactions from team officials, including Ferrari’s sporting director and Mercedes’ engineering director, demonstrate the challenges teams face in balancing speed with regulatory adherence. As the sport continues to evolve, it is vital for teams to foster a culture of diligence and accountability regarding their car’s design features, including the skid block, to avoid penalties that could jeopardize their championship aspirations.

The Relationship Between Aerodynamics and Skid Block Design

Aerodynamics plays a pivotal role in the performance of Formula 1 cars, and the design of the skid block is no exception. While its primary function is to protect the car’s floor and ensure driver safety, the skid block must be designed in a way that complements the overall aerodynamic profile of the vehicle. As the car travels at high speeds, the airflow around the skid block can significantly impact downforce and drag, two critical factors for competitive racing.

Consequently, engineers must carefully consider the materials and shape of the skid block to minimize any adverse effects on aerodynamics. Advanced simulation techniques and wind tunnel testing are often employed to analyze how the skid block interacts with the rest of the car’s design features. This attention to detail exemplifies how every component, including the skid block, contributes to the broader goals of speed and efficiency in Formula 1 racing.

The Evolution of Skid Block Regulations in F1

The regulation of skid blocks in Formula 1 has evolved significantly since their introduction, reflecting the sport’s commitment to safety. Initially introduced in response to tragic incidents, these regulations have since been refined to ensure that they effectively enhance driver protection without compromising performance. The requirement for a skid block of uniform thickness is a prime example of how regulatory bodies seek to create a safer racing environment while maintaining the integrity of the competition.

As technology progresses, so too do the materials and designs used in skid blocks. Teams are now exploring innovative solutions that offer greater durability and less weight, while still complying with safety standards. This evolution demonstrates the adaptability of Formula 1 to both technological advancements and the ongoing need for enhanced safety measures, ensuring that the sport remains at the forefront of motorsport engineering.

Challenges in Maintaining Skid Block Integrity

Maintaining the integrity of the skid block throughout a race is one of the key challenges faced by Formula 1 teams. Factors such as track conditions, driving style, and the setup of the car can all contribute to the rate of wear on the skid block. Teams must employ a range of strategies, including pre-race inspections and in-race monitoring, to ensure that the skid block remains within the regulated limits. Failure to do so can result in disqualification, emphasizing the critical nature of this component.

Moreover, the pressure of racing against the clock adds another layer of complexity. Teams often have to make quick decisions regarding car adjustments, which can inadvertently affect the skid block’s performance. This balancing act between optimizing the car for speed and ensuring compliance with safety regulations requires a high level of expertise and foresight from engineers and drivers alike. The ongoing focus on skid block integrity is a testament to the meticulous nature of Formula 1 racing.

Future Innovations in Skid Block Technology

As Formula 1 continues to push the boundaries of technology and safety, future innovations in skid block design are likely to emerge. The integration of advanced materials, such as composites or alternative woods, could provide a more robust solution that withstands wear and tear better than traditional options. Engineers are exploring ways to enhance the skid block’s performance without compromising its primary safety functions, signaling a new era in F1 design features.

Moreover, as the sport shifts towards sustainability, the materials used for skid blocks may also evolve to incorporate eco-friendly practices. The future of Formula 1 racing is not only about speed and performance but also about responsibility towards the environment. Innovations in skid block technology will therefore play a vital role in shaping the next generation of racing cars, blending safety, performance, and sustainability in a way that resonates with modern values.

Frequently Asked Questions

What is the function of the skid block in Formula 1 cars?

The skid block, also known as a wooden plank, serves to protect the car’s floor while limiting downforce to enhance driver safety. It is designed to wear down gradually, ensuring that the car maintains a higher ride height and reducing the risk of losing control over bumps.

How does the skid block relate to F1 safety regulations?

The skid block is a key component of F1 safety regulations, introduced to prevent accidents like those seen in the 1994 San Marino Grand Prix. By maintaining a specific thickness, the skid block helps ensure that cars do not sit too low, thus improving driver safety during races.

What are the design features of the skid block in Formula 1?

Formula 1 skid blocks are made of wood and must maintain a uniform thickness of one centimeter during races. Teams can use metal plates to reduce wear in designated areas, ensuring compliance with regulations and enhancing safety.

How does the skid block impact Formula 1 car aerodynamics?

The skid block impacts F1 car aerodynamics by regulating the ride height, which in turn influences airflow and downforce. A higher ride height, enforced by the skid block, helps maintain stability, especially on uneven surfaces.

What happens if a Formula 1 car’s skid block is too worn?

If a skid block is found to be excessively worn after a race, the team risks disqualification. This regulation ensures that teams adhere to safety standards, maintaining the skid block’s required thickness throughout the event.

Why was the skid block introduced in Formula 1?

The skid block was introduced in response to fatal accidents in the 1994 San Marino Grand Prix, aimed at enhancing driver safety by preventing cars from being too low to the ground, which could lead to loss of control.

What are the consequences of skid block violations in Formula 1?

Teams face disqualification if their skid blocks do not meet the required thickness after inspection. This strict regulation promotes adherence to safety standards and ensures fair competition.

How is the wear on the skid block assessed in Formula 1?

Wear on the skid block is assessed at four designated spots on the underside of the car after each race. Teams are allowed to use metal plates in these areas to mitigate wear and comply with regulations.

How did recent events impact the skid block regulations in Formula 1?

In 2023, drivers Lewis Hamilton and Charles Leclerc were disqualified due to excessive wear on their skid blocks, highlighting the importance of strict adherence to skid block regulations and the consequences of oversight.

What are the future implications for skid block regulations in Formula 1?

As F1 moves towards more sustainable practices and new engine regulations by 2026, the skid block’s role in safety and design will likely evolve, potentially incorporating new materials or technologies to enhance its effectiveness.

| Key Point | Description |

|---|---|

| Skid Block Purpose | Protects the car’s floor and regulates downforce for driver safety. |

| Historical Context | Introduced after fatal incidents in 1994 to enhance driver safety. |

| Regulations | Must maintain a thickness of 1 cm, with a maximum wear of 1 mm per race. |

| Disqualification Risks | Drivers face disqualification if skid block is too thin post-race. |

| Recent Events | Hamilton and Leclerc disqualified in 2023 due to excessive wear on skid blocks. |

Summary

The Formula 1 skid block is a crucial component that plays a vital role in ensuring driver safety and maintaining car performance. Designed to protect the car’s floor and manage downforce, this wooden plank may seem out of place in high-speed racing, yet it is essential following historical tragedies in the sport. With strict regulations on its thickness and wear, the skid block exemplifies how Formula 1 continuously evolves to prioritize the safety of its drivers while pushing the boundaries of speed and technology.